ELECTRONIC INTEGRATION

When developing products, we define the PCB in conjunction with the electronic engineer to ensure it can be fully integrated with the rest of the device.

SENSOR CONTACT BLOCK

For many diagnostic devices, small multiple contacts are required at narrow pitches. The development of an in-mould contact block delivers device reliability.

DIAGNOSTIC TESTING

Considerable testing prior to defining the finished product is crucial. We design proof-of-principle test rigs on which we can undertake this early testing.

ELECTRONIC DEVELOPMENT

We often need to manufacture prototype PCBs and prototype case-mouldings to produce working prototypes for testing and approval, prior to production.

“We help you take advantage of emerging technology”

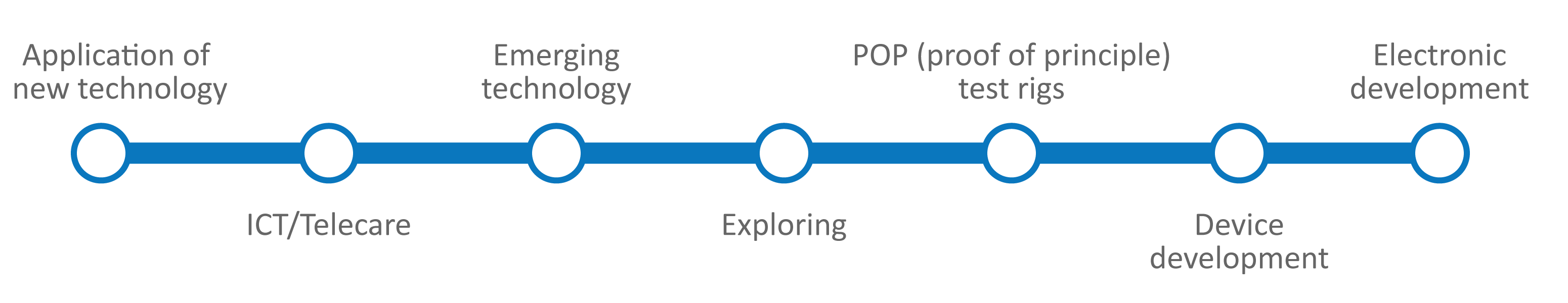

Research and development and designing proof-of-principle test rigs are a fundamental activity within Gm Design Development UK

R&D based activities play an important part in the development of any product. We see this as a creative process that takes place at an early stage of the development of a product. We actively research new technologies, looking how they can be utilised in new products. We build prove-out rigs to verify the application of the technology. This can be a crucial stage where IP can be created and protected. We can help with these activities by working with patent attorneys, producing the drawings so patents and design registrations can be applied for.

Application of new technology

Our design team is always looking at how new technologies can be used in the products we develop. Considering electronic components such as OLEDs, flexible displays – looking at how they might improve the existing design of the product.

ICT/Telecare

This has become increasingly important within many of the healthcare and medical products we design. Many products link directly back to clinicians, with some devices monitoring patients in real-time.

Emerging technology

We keep abreast of emerging technology and how it could influence how future products should be designed.

Exploring

We research advances in technology such as materials, finishes as well as manufacturing processes such as 3D Printing.

POP (proof of principle) test rigs

We aim to test key aspects of a design, using test rigs to ensure all aspects work reliably. This could be mechanisms, microfluidics, etc.

Device development

We develop the design in 3D CAD and use the testing undertaken on the test rigs to help guide the design. We use the 3D data to prototype the components and build the entire product.

Electronic development

We have worked with DC Allen - an electronic and software product development company for over 10 years. (See THE TEAM page for details). This allows us to offer the full design service. We define the electro-mechanical design fully within our 3D CAD package ensuring the design is integrated with any case mouldings.