PRODUCT ARCHITECTURE

We develop sheet metal fabricated products. The system is made from common components, using custom parts to vary the height of each module.

DETAILED PRODUCT DESIGN

We define the complete product assembly fully in 3D CAD, including the electro-mechanical definition, ensuring the mouldings snap together reliably.

INJECTION MOULDING DESIGN

The external form of the product is defined using complex surface modelling, dividing it into parts to detail all the internal features.

SHEET METAL FABRICATION USING 3D CAD

Our specialised sheetmetal 3D CAD module allows us to design fabricated products accurately. Component data is issued as flattened patterns for manufacture.

“Our engineering expertise allows us to deliver technically challenging products”

Design & engineering at Gm Design Development UK - Creo & SolidWorks 3D CAD experts.

Components are fully engineered in detail ready for production. A full manufacturing specification is produced including 2D component/assembly drawings along with a full Bill of Materials.

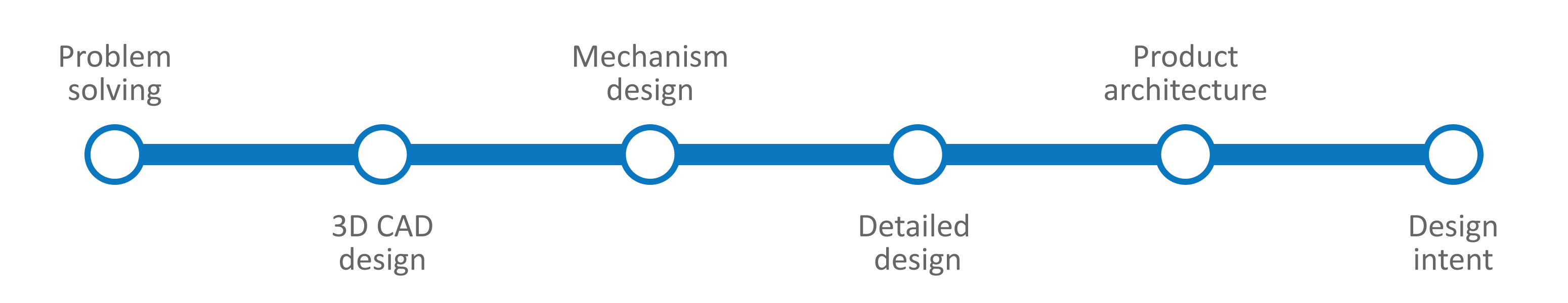

Problem solving

Whether we are designing a medical device or a consumer product, the need to generate solutions to solve problems is a common requirement. Our creative engineering team will always look to overlook them with clever use of design.

Product architecture

Using 3D CAD, we fully define complex assemblies, including electronic sub-assemblies that are integral to the product.

Detailed design & 3D CAD

We use advanced surface modelling to define the product form and aesthetics. The mouldings are then fully detailed.

3D CAD allows us to undertake some fundamental analysis of components, including FEA (finite element analysis), clearance and interference checks and draft analysis to ensure components are suitable for manufacture.

Mechanism design

We use specialist software within our 3D CAD package to define mechanisms allowing the complete movement to be analysed.

Design intent

We define the design intent into the 3D CAD from the start, so these principles remains throughout the detailed design process to the final product.